COLOURS & FINISHES

Monocouche XF Standard Colours

The Monocouche XF system is available in the following 10 standard colours which we aim to have in stock at all times however due to the diversity of our client base and the random nature of sales we advise that orders should be planned as far as possible in advance.

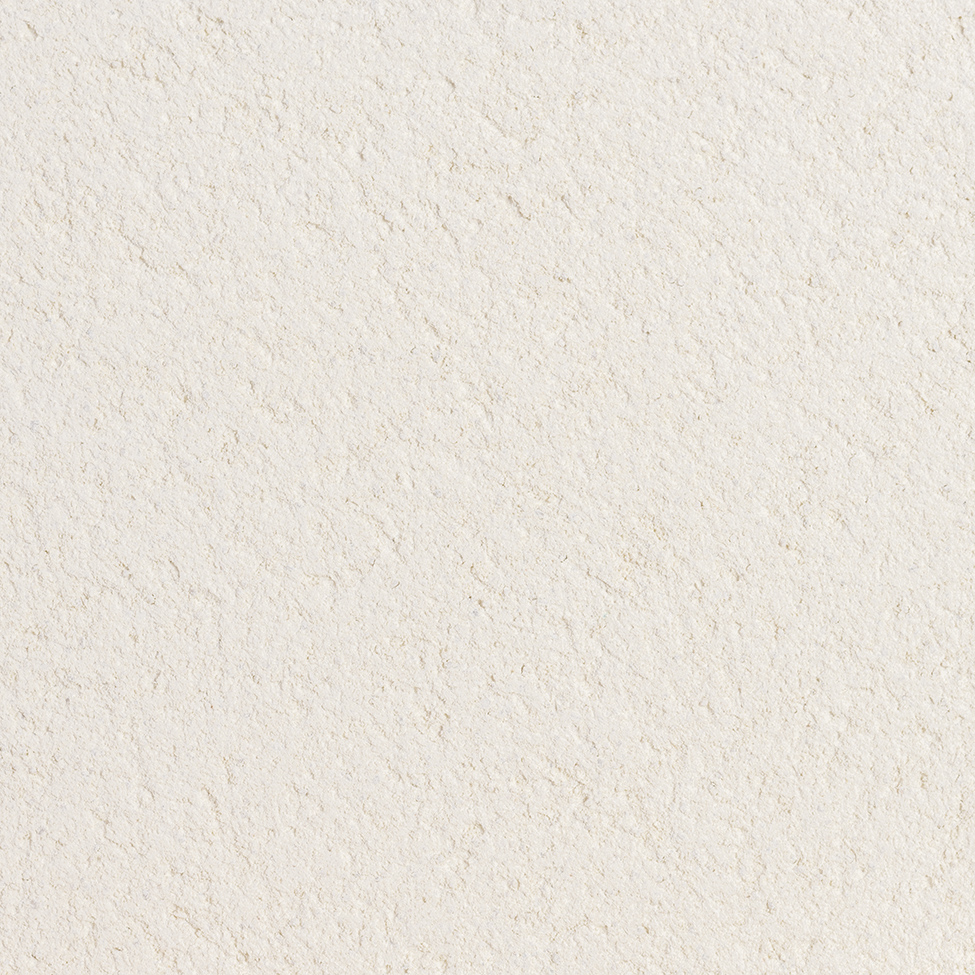

XF Nimbus White

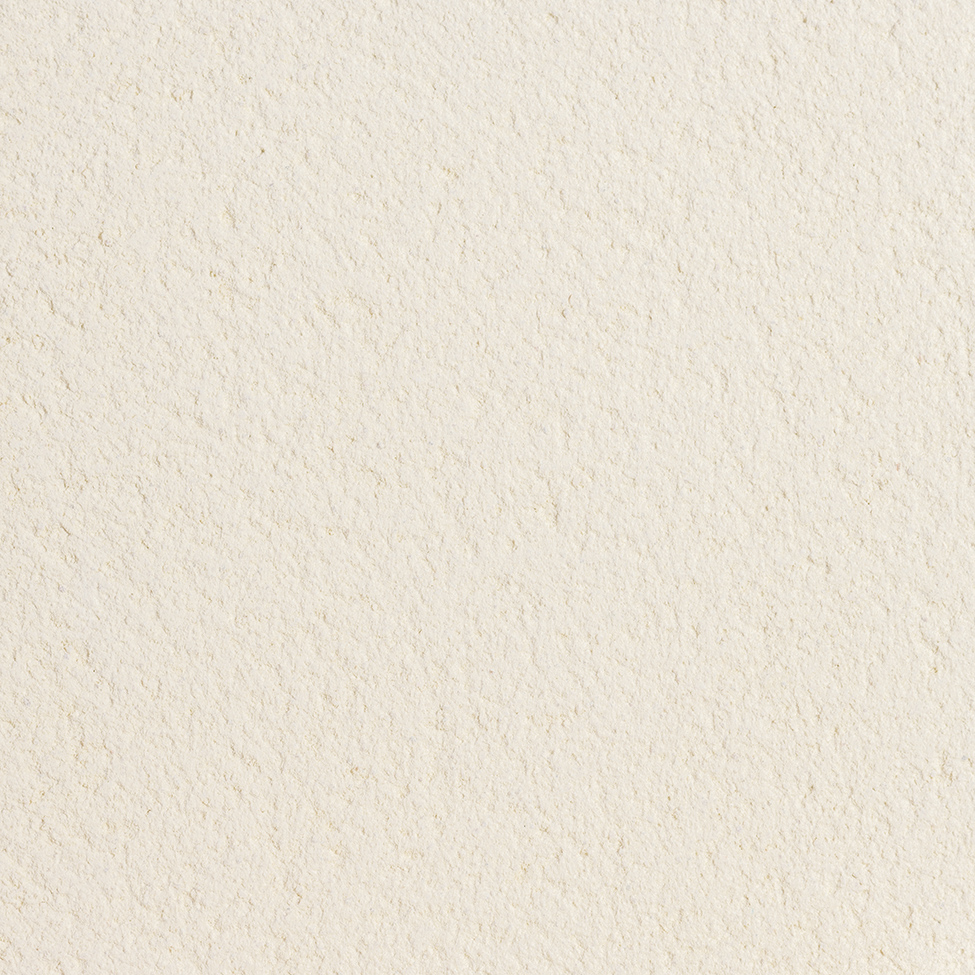

XF Chalk White

XF Heritage White

XF Dove Grey

XF Ash Grey

XF Light Beige

XF Ivory

XF Cream

XF Sand

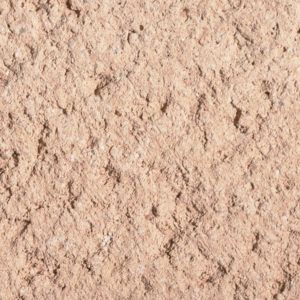

XF Dark Beige

The appearance and shade of the above sample photos and below project examples will change dramatically from screen to screen and device to device. We advise that samples are requested to get a better but understanding of the chosen colour/s. If the precise finished shade of a particular colour is of such high importance a sample bag of the selected material should ordered and applied at site and allowed to dry for final approval.

XF Nimbus White

We are very proud to offer XF Nimbus White; our whitest ever Monocouche render.

This stunning material has been created by using the whitest base aggregates available to us. Delivering a bright, clean external finish, this render really shines when the sun bounces off its glowing surface.

XF Chalk White

Our very popular chalk white render produces a slightly muted, cooler white. Less intense than the XF Nimbus White, it achieves a stunning, crisp, softer white colour finish.

XF Heritage White

Completing our range of whites, XF Heritage White is our warmest and most traditional of the white colour finishes. It’s been said that it has a comforting hue, like a luxurious double cream.

XF Dove Grey

This stunning grey tone is the lightest of our grey colour finishes. It presents very subtly in the sun and then takes on more depth of shade as the light leaves its surface.

XF Ash Grey

Our dark grey colour finish picks up where XF Dove Grey leaves off and goes further. The deeper grey tones manifest in stunning versions of ash and charcoal as the light moves across it.

XF Light Beige

This subtle, warm hue sits confidently in the range as an alternative to the white and ivory colour finishes. It offers shades of soft and muted greyish browns.

XF Ivory

We are renowned for how light, subtle and creamy our stunning XF Ivory render is. It stands out in comparison to others on the market, that generally have a more yellow tone.

XF Cream

This beautiful material is a slightly warmer variation, on the same spectrum as our XF Ivory but more traditional. It is what we would call a true cream colour finish.

XF Sand

At the end of the ivory and cream spectrum sits this wonderfully deep and vibrant statement colour finish. It has been likened to the lissful tone of a Mediterranean beach on a warm sunny evening.

XF Dark Beige

This stunning darker beige render displays a wonderfully light toffee or caramel hue. It is a step towards natural wood, transitioning into to deeper and more robust tones when the light disappears.

The Monocouche XF system is also available in the following non-standard colour finishes. These options are manufactured to order with the following considerations:

- Additional cost in comparion to standard colours

- Extended lead time

- Minimum order quantity of 80 bags/m2

We only accept orders of full pallets thereafter (i.e. 120, 160, 200, 240, 280, 320…)

XF Buttermilk

XF Truffle

XF Mustard

XF Sahara

XF Ash Grey

XF Sage

XF Earth

XF Mocha

XF Rose

XF Salmon

XF Brick Red

XF Terracotta

Monocouche XF Finishes

The Monocouche XF system has been developed to give its users the flexibility to achieve a variety of external finishes using the same system components.

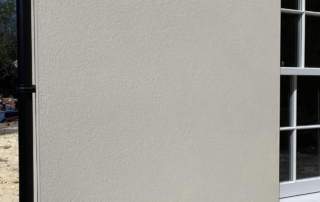

Scratch finish

Scratch finish is a decorative application, achieved by removing the top layer of material with a scratch/nail float to reveal a beautifully random, but generally uniform, texture.

Rough Cast Finish

Rough cast textured finish is created by adjusting the render installation machine to project and spatter the material in the desired consistency. The depth, roughness, frequency and general appearance of this traditional render style is then altered by changing the speed of the passes.

Sponge Finish

Sponge finish mimics the flat, dragged sand appearance of traditional sand and cement render. It is achieved by adding an additional layer to the semi cured material and then using a sponge to finish. This takes place once the material has cured enough to resist the pressure of the finishing technique.

Trowel Finish

Trowel finish is a cost and time saving alternative to building with traditional stone. This render finish is achieved by adding an additional layer to the semi cured material and then using a trowel to finish once the material has cured enough to resist the pressure of the finishing technique.

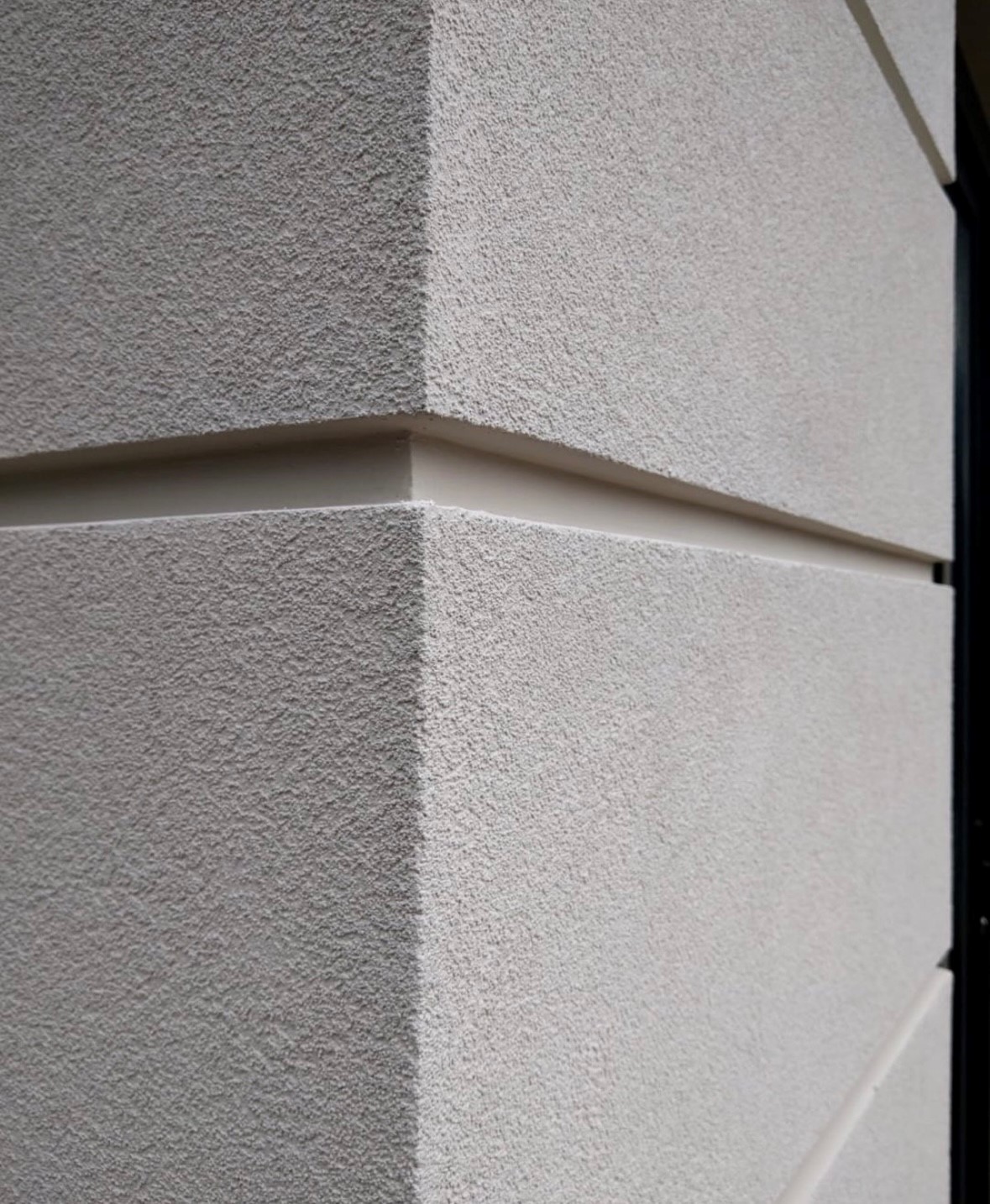

XF Ashlar Lines

Ashlar lines are cut from the Monocouche XF material to mimic the decorative grooves that are present in some forms of traditional stone construction. The grooves can also be used to frame windows and create embellishments.

EWI Ashlar Lines

Ashlar lines are formed using insulation panels to mimic closely the decorative grooves that are present in some forms of traditional stone construction. The grooves can also be used to frame windows and create embellishments.

Coursing Lines

Subtle lines can be scored into to the trowel finished render to appear like masonry courses. These lines can be as wide as required to mimic any size of masonry and configured to match traditional masonry bonding patterns.

The installation of the Monocouche XF system is a specialist undertaking that should only be carried out by experienced and, where possible, approved contractors.

The successful application of the various finish styles relies on the skill and experience of the installing contactor. We advise requesting examples of work and references from previous projects, in the desired style and colour finishes, prior to works commencing.

The final shade of all Monocouche render colour finishes does vary. It is dictated by how soon the water within the newly-applied material is removed by the weather conditions during installation and the type of substrate.

The absolute lightest shades of all tones, including whites, are achieved in the warm and dry spring and summer months when the material cures faster than in the cold, dark and damp autumn and winter months.

If the precise shade of a specific colour is of high importance a physical render sample should be applied to the substrate at site and allowed to dry fully before client review and approval.