SILICONE RENDER

Silicone render is the breathable, flexible, lightly textured and coloured finish that decorates and protects external wall insulation (EWI) and thin coat render systems.

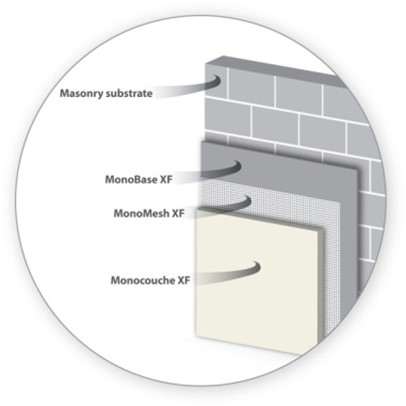

The base coat, mesh, primer and silicone finish components within EWI systems, that are used to cover the insulation, can also be applied directly onto masonry, render carrier board and ICF construction. This is why the installation of these elements without insulation is often referred to as “silicone render only”.

The way in which the silicone finish is manufactured means it can be mixed to closely match all of our Monocouche XF colours, RAL codes and even some well know paint manufactures colour titles.

We have worked in partnership with several industry leading silicone render system manufacturers for many years and are certified to offer their systems on a fully warrantied turnkey supply and install basis.

KEY SYSTEM BENEFITS

- Available in all colours of our Monocouche XF system range

- Can also be mixed to closely match RAL and NCS colour codes

- Able to achieve a consistent finish across masonry, insulated, ICF and boarded substrates

- Profile beading edges are not visible in the finished product

- Increased thermal performance when combined with a suitable external insulation

- Suitable for application to external soffit/ceiling areas

- Excellent colourfastness and high resistance to UV light

- High level of protection against dirt and algae build up

- Low maintenance without the need to paint and repaint

- Weatherproof and far more durable than traditional sand and cement renders

- 10 Year system warranty available through specification

SILICONE RENDER (ONLY) A BASIC GUIDE

MASONRY CONSTRUCTION

The benefits of high performance silicone render can be enjoyed on projects constructed entirely of masonry.

Silicone render can also be installed where masonry panels are present within a scheme that has insulated or render boarded surfaces also to achieve a consistent finish throughout.

- A high polymer base coat is applied at 10mm over the masonry and when suitably dry the base coat is primed in preparation for the final through colour decorative silicone layer.

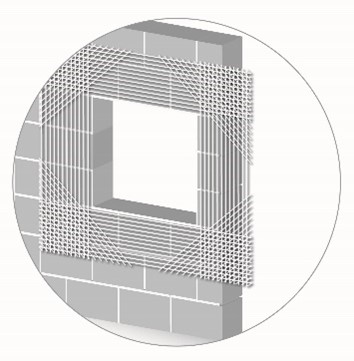

- Alkali resistant mesh is imbedded between the two base coat layers whilst wet.

- 10mm PVCu are installed to encapsulate the base coats and give definition to the finished product.

Silicone render onto stable masonry system thickness guidance:

10mm of base coat + 1mm – 2mm of silicone finish = approx. 12mm.

TIMBER & STEEL FRAME CONSTRUCTION

In timber frame, steel frame and SIPS construction, where the insulation is achieved within the framework structure or internally, the silicone render system is installed onto the enclosing render carrier board.

- High polymer base coat is applied in two coats to the render carrier board and when suitably dry the base coat is primed in preparation for the final through colour decorative silicone layer.

- Alkali resistant mesh is imbedded between the two base coat layers whilst wet.

PVCu and mesh beads are installed to encapsulate the base coats and give definition to the finished product. - Silicone render onto render carrier board system thickness guidance:

6mm of base coat + 1mm – 2mm of silicone finish = approx. 8mm + thickness of render carrier board.

A system using a 12mm render carrier board would total approximately 20mm in thickness from the outer face of the battening.

The required battening configuration onto which the render carrier board is fixed may differ between system manufacturers and building warranty providers with some requesting a single vertical batten and others both vertical and horizontal. We strongly advise seeking confirmation of the required battening layout from your warranty provider to ensure that building warranty guidelines will be met.

If you require a warranty for the total render carrier board and silicone render system all components including the render carrier board, fixings and the silicone render system should be purchased from the same manufacturer and as Importantly installed by a contractor who is registered and certified by them.

EXISTING PAINTED MASONRY OR RENDER

We offer a warrantied specification for silicone render onto existing and stable painted masonry or render.

After review, if the painted substrate is deemed to be suitable this method of install would remove the need to remove the paint or render therefore saving time, cost and intrusion.

To achieve warranty, we would have to prepare the substrate by methods such as anti-fungal cleaning, scoring, priming and or installing mechanical fixings to ensure sufficient key and connection with the masonry behind.

We may also need to remove the opening reveals and heads to ensure the new system meets with the existing window and door frames correctly.

Silicone render onto existing painted masonry or render system thickness guidance:

10mm of base coat + 1mm – 2mm of silicone finish = approx. 12mm.

INSULATED CONCRETE FORMWORK (ICF)

In ICF construction the silicone render is installed directly onto the ICF structure.

- High polymer base coat is applied in two coats to the ICF structure and when suitably dry the base coat is primed in preparation for the final through colour decorative silicone layer.

- Alkali resistant mesh is imbedded between the two base coat layers whilst wet.

10mm PVCu are installed to encapsulate the base coats and give definition to the finished product.

Silicone render onto ICF construction thickness guidance:

10mm of base coat + 1mm – 2mm of silicone finish = approx. 12mm.

HOW CAN WE HELP YOU WITH YOUR SILICONE RENDER PROJECT?

We offer a fully warrantied turnkey supply and install service for silicone render using our own in house teams.

We can also supply and install the render carrier board background therefore meeting the criteria to achieve warranty for the entire silicone onto render board system.

To find out more about more how we deliver our industry leading risk removing turn key supply and install service please feel free to check out Render Installation and send us an Enquiry and we will be happy to assist.

Check out our Project Gallery to review some of our previous projects and follow us on our social media platforms below to benefit from regular updates and honest, experience-driven insights.