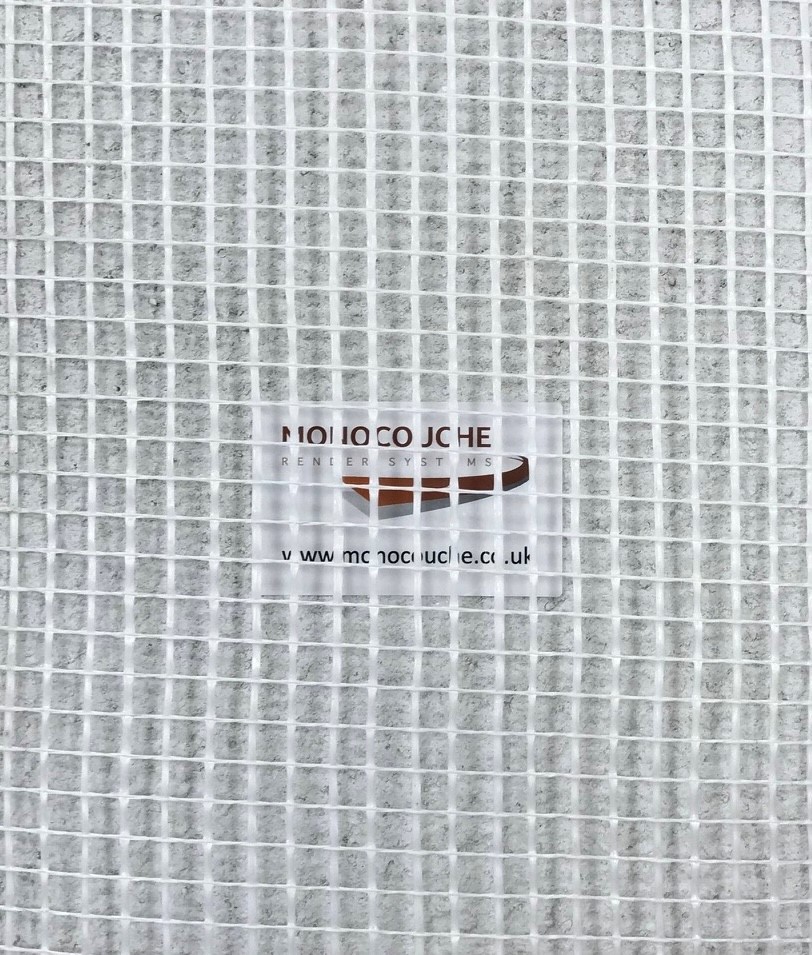

MonoMesh XF Stress Mesh

£66.00 inc. VAT

Price ex. VAT: £55.00

Delivery ex. VAT: £50.00 per consignment

No charge if purchased with Monocouche XF and/or MonoBase XF

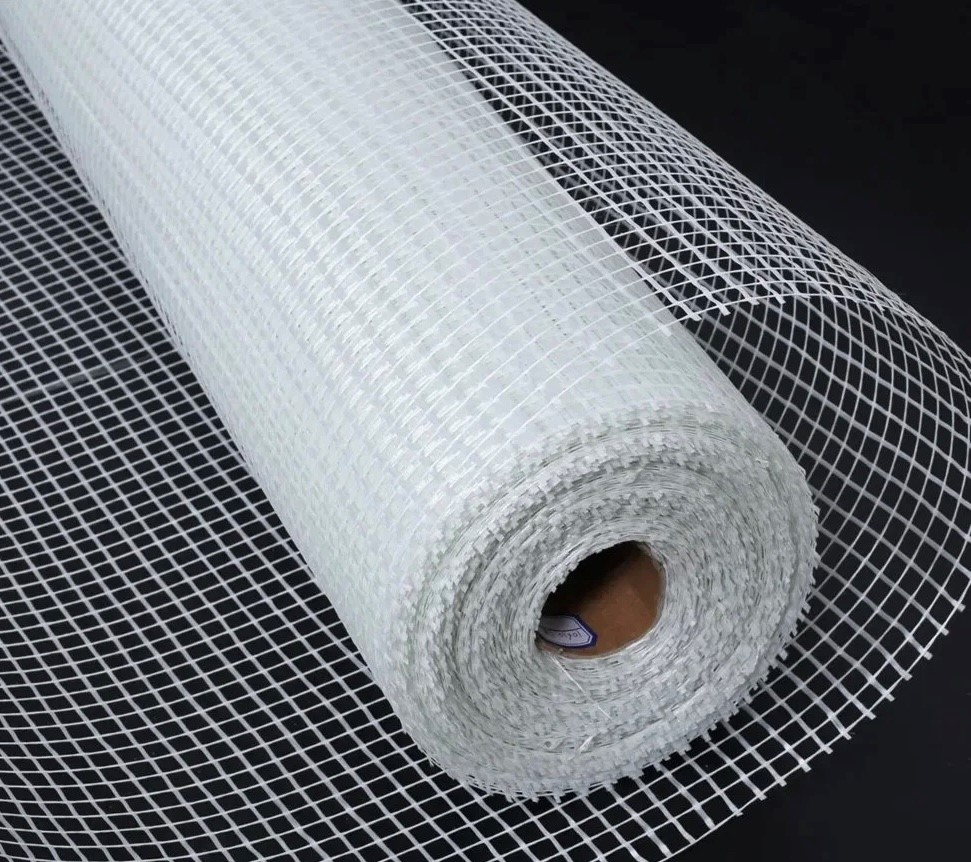

Coverage: 50m2 per roll (50m x 1m) 45m2 per roll allowing for 100mm overlap

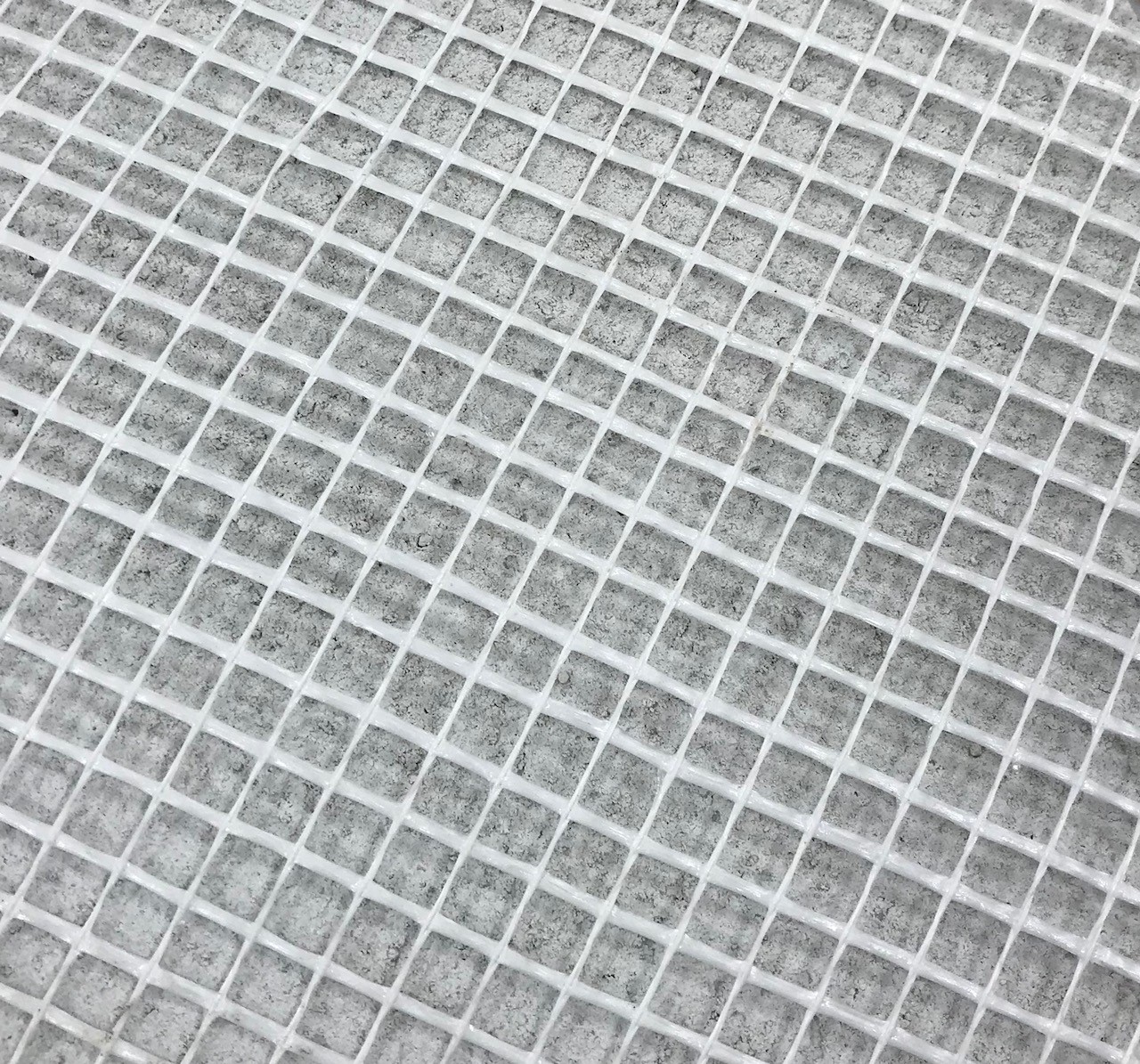

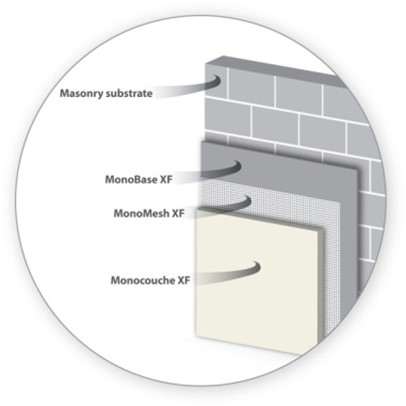

High performance premium quality alkali resistant mesh to be imbedded within the MonoBase XF or Monocouche XF layer to reinforce and greatly increase protection against movement within the masonry substrate.

The only mesh cloth supplied in the industry with 10mm x 10mm apertures that allow more material to pass through and form a super integrated stress absorbing bandage.

KEY BENEFITS

- Increased protection against movement within masonry

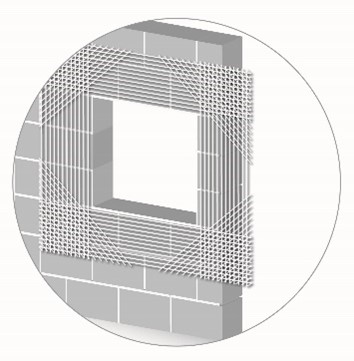

- Increased reinforcement at openings and stress points

- Improved dispersion of stress

- Easy to cut with a knife or scissors

- Product Description

- Additional Information

- Installation Guidance

- Technical Support

- Delivery & Returns

- System Warranty

Product Description

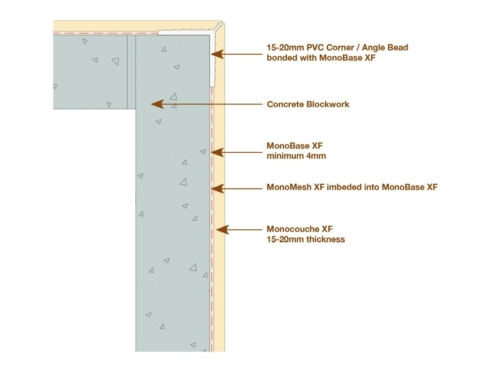

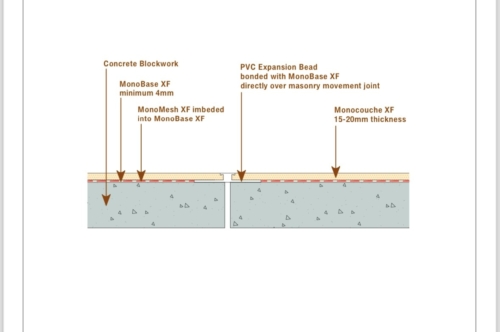

Monocouche XF can be installed onto stable masonry including general purpose concrete block, lighter-weight and lessor-density aircrete block, brickwork, stonework and concrete with the support of a layer of MonoBase XF polymer modified base coat. For best practice, we also advise imbedding MonoMesh XF throughout.

This comprehensive approach provides a consistent base layer without impurity. In turn, this controls and equalises suction onto which the through coloured Monocouche XF coating is applied. This protects the render system against issues which may be caused due to the condition and behaviour of the masonry substrate. The addition of the MonoBase XF and MonoMesh XF layer provides greater resistance to movement within the substrate and increases protection against water penetration and weathering. A PDF describing Monocouche XF best practice installation can be downloaded from our Technical Reference section and shared with site management staff and installing contractors.

Additional Information

Render System – Monocouche XF

Product – MonoMesh XF

Sold in – 50m2 Rolls (10kg each)

Coverage – 50m2 per roll (50m x 1m) 45m2 per roll allowing for 100mm overlap

Pallet Qty – 30 x 10kg rolls (300kg)

Installation Guidance

Best Practice Installation

Monocouche XF can be installed onto stable masonry including general purpose concrete block, lighter-weight and lessor-density aircrete block, brickwork, stonework and concrete with the support of a layer of MonoBase XF polymer modified base coat. For best practice, we also advise imbedding MonoMesh XF throughout.

This comprehensive approach provides a consistent base layer without impurity. In turn, this controls and equalises suction onto which the through coloured Monocouche XF coating is applied. This protects the render system against issues which may be caused due to the condition and behaviour of the masonry substrate. The addition of the MonoBase XF and MonoMesh XF layer provides greater resistance to movement within the substrate and increases protection against water penetration and weathering. A PDF describing Monocouche XF best practice installation can be downloaded from our Technical Reference section and shared with site management staff and installing contractors.

MonoBase XF applied to 4mm thickness onto masonry MonoMesh XF imbedded into entire MonoBase XF layer Monocouche XF finished flush with 15mm PVCu beads Total system thickness 15mm + depth of bead bedding

Direct – One Coat Installation

Monocouche XF can also be applied in one coat onto suitable open-faced, 7kn, general purpose concrete blockwork.

The masonry substrate should be constructed with a sufficient movement control design containing bed joint reinforcement and or expansion joints. We strongly advise following masonry manufacturers guidelines, in conjunction with BS 5628-3 Code of practice for use of masonry and BS 6093 Code of practice for design of joints and jointing in building construction.

The key to a successful one coat installation relies on the selection of a suitable block type and the management and control of materials. Professional workmanship during the construction of the substrate and the inclusion of a suitable movement control design will ensure that the blockwork performs as it should when constructed. Further guidance on constructing to receive Monocouche XF render in one coat can be found within the XF Construction Guide

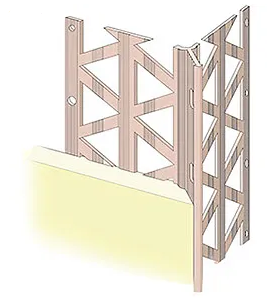

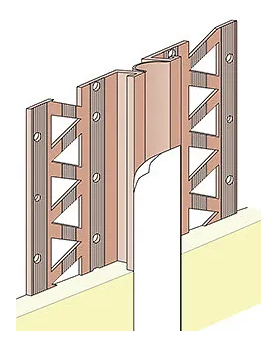

MonoMesh XF should be installed to pass the area of weakness by at least 500mm vertically and 250mm horizontally. A second layer of MonoMesh XF should be installed diagonally across the corners of openings to create a reinforced stress absorbing patch.

Technical Support

The complete suite of supporting technical data and guidance can be found within the Technical Reference section of our website where PDF installation guides can be downloaded and shared with the installing party.

It is advised that Monocouche Render Systems is consulted to gain a complete understanding of the system prior to commencement of works at site.

Contact: 0330 111 1467 / info@monocouche.co.uk

Samples: Available upon request

Delivery & Returns

STANDARD DELIVERY TERMS

Your materials will be processed for delivery on the next available standard delivery service unless you state otherwise.

If you do not wish to receive your materials immediately, please specify the earliest date you want to receive them in the order notes section of the checkout.

- Standard weekday delivery within 2 – 3 working days of confirmed order.

- Day and date of planned delivery to site will be confirmed soon after initial order confirmation.

- Standard weekday delivery arrives on a rigid lorry at no specific time between 8am and 5.30pm.

- Standard weekday delivery allows for our vehicle to offload with a tail lift and pallet truck.

- The pallets must be offloaded “kerb side” onto a suitable solid hard standing such as road, driveway or path.

- Due to the weight of the pallets we cannot deliver onto gravel or stone finished areas.

- Re-delivery charges may be applied should the delivery fail due to site access and or readiness.

- We request that the driver of every consignment calls within one hour of arriving on site but unfortunately we cannot guarantee this.

TYPICAL DELIVERY TIMESCALES

Your materials will be processed for delivery on the next available standard delivery service unless you state otherwise.

If you do not wish to receive your materials immediately, please specify the earliest date you want to receive them in the order notes section of the checkout.

After our initial confirmation of the receipt of your order, we will then send a second confirmation when your order has been dispatched;

| Order Confirmed | Day of Delivery to Site |

| Order confirmed as dispatched before 11am on Monday | Delivery on Wednesday 8am – 5.30pm |

| Order confirmed as dispatched before 11am on Tuesday | Delivery on Thursday 8am – 5.30pm |

| Order confirmed as dispatched before 11am on Wednesday | Delivery on Friday 8am – 5.30pm |

| Order confirmed as dispatched before 11am on Thursday | Delivery on Monday 8am – 5.30pm |

| Order confirmed as dispatched before 11am on Friday | Delivery on Tuesday 8am – 5.30pm |

PVCu beads will arrive on a separate delivery by another carrier on or before the day of render material delivery.

Delivery timescales may vary during periods of national and bank holidays.

We offer the above timescales as a guide but unfortunately due to the well reported national driver shortage throughout UK pallet networks we do suffer the occasional delay which is completely out of our control and therefore we cannot be held responsible for any delays, losses or costs suffered in these quite rare instances.

Moffet offload, Next day and Saturday deliveries may be available on request.

Please contact sales@monocouche.co.uk to confirm availability and pricing.

It is our advice that materials are ordered to site a few days in advance of when they are required for install.

Please take the time to ensure that you have ordered enough materials to avoid additional delivery charge & delay.

We suggest that the installing party provides the purchaser with the material quantities required.

RETURNS POLICY

Due to the nature of the products we do not accept returns.

System Warranty

We supply a 10-year system warranty with all materials and systems manufactured by MRS (XF, TXF & RXF)

If a warranty or specific accreditation is required for one of our systems, this should be requested in writing at the time of purchase and prior to the system/s being installed.